Front line medical workers across the globe have been using technology including robots, telemedicine to help contain the COVID-19 pandemic that has brought the world to a standstill.

Almost a month ago, a field hospital staffed by robots opened in the Hongshan Sports Centre in Wuhan, China, where the pandemic began. All medical services in the hospital — like screening, monitoring of heart rate, temperature, blood oxygen levels — were carried out by robots and other IoT devices. In fact, these robots also provided food, drinks, medicine to the patients and also cleaned the floors.

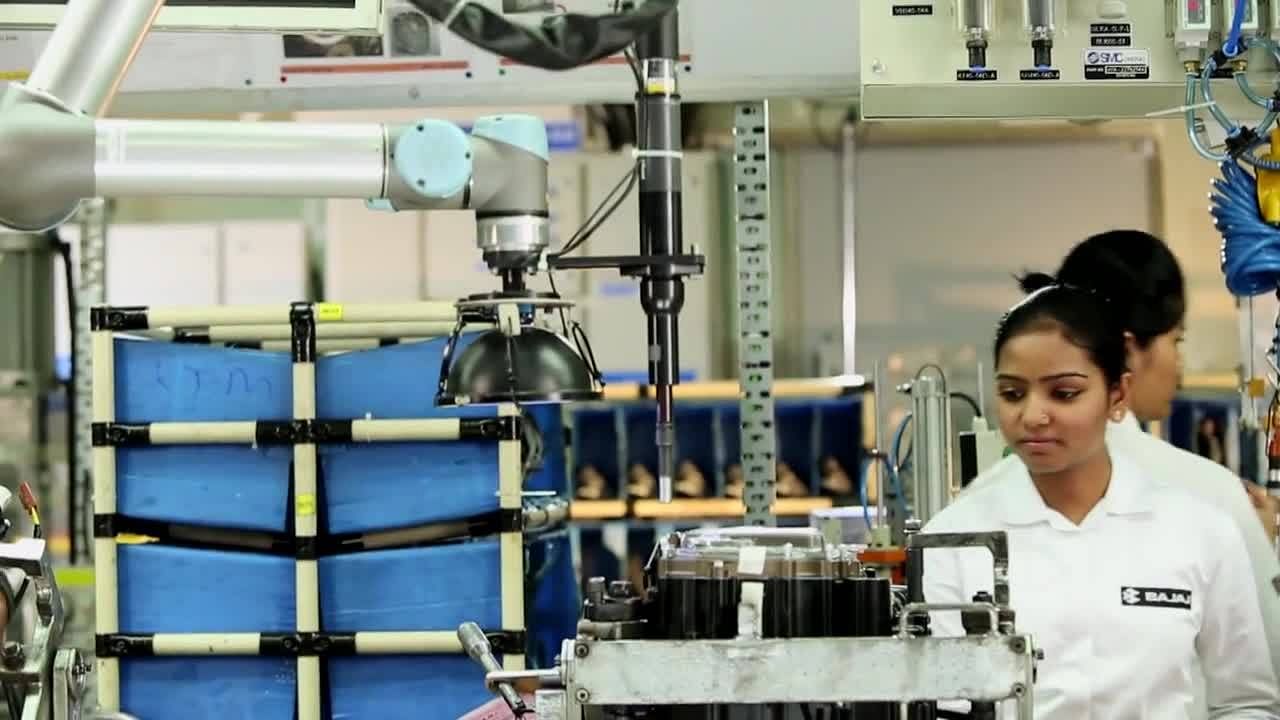

Cobots, or collaborative robots, are robots designed to work alongside humans in a shared space, to increase productivity. Universal Robots, headquartered in Denmark, has been the market leader for cobots for several years now. Pradeep David, General Manager, South Asia, Universal Robots, in a conversation with DH, talks about the significance of cobots in the backdrop of COVID-19.

“Doctors are scared now. Imagine a robot that can work like a human arm, which can rotate 360 degrees. if humans can control it remotely, there are so many things we can do with cobots including checking the temperature, heartbeat of a person sitting in the next room, without risking one’s own safety,” David explains.

David says, ”The MSME segment is extremely dependent on labour. Even now, when COVID-19 will fade away and factories open up, one of the biggest problems will be to get back labour force that may have moved to their native places. Even though it’s believed that labourers are abundant in India, the fact is, if you talk to SMEs, the most unreliable part of their business is the labour force. Productivity is very critical for them, and that’s where robots come in the picture.”

The company, which has 300 partners around the world, started its India operations in February 2016. Universal Robots has over 42,000 cobots installed around the globe as of today. Bajaj Auto is one such customer in India with over 100 cobots in its manufacturing facilities. The company has other clients like Aurolab, Madurai, L'Oréal plant in Pune among others.

Talking about the impact of COVID-19 on the company, David says, “We are a Danish company, and the cobots are manufactured in Denmark. But knowing this was coming, if for some reason Denmark factory has to close down, we have stocked 200 robots in Malaysia, and some in Singapore, China and the US. We have taken into account that the supply chain for our customers should keep on going.”

India’s adoption rate of robots is one of the lowest in the world, mentions David. “It has been the case because of various issues like — expense, job losses, the difficulty of operation. However, cobots have shown themselves to be operator friendly. They are not designed to act as substitutes, in fact, they have helped in job creation. In the long run, our main focus is going to be on the SMEs sector. When we bounce back, after the pandemic retreats, we’ll be ready for them,” he says.