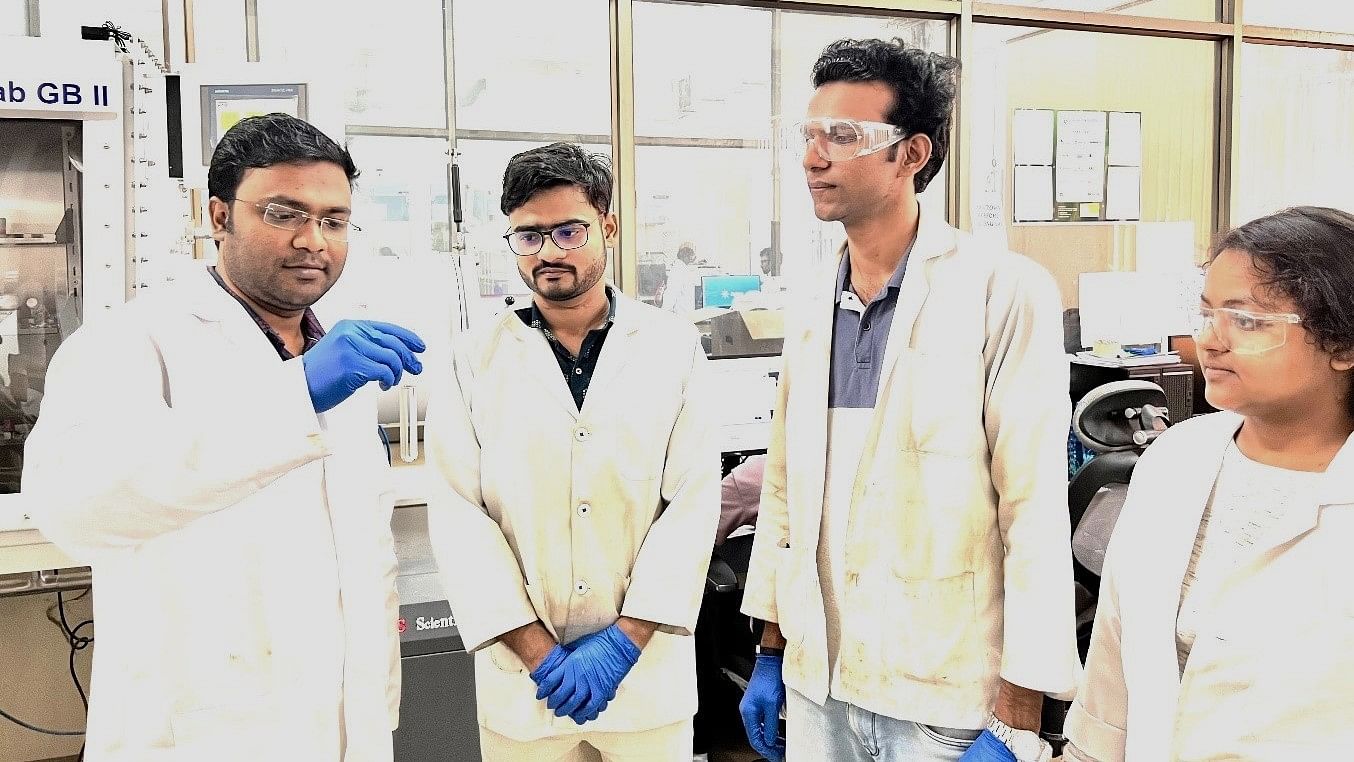

(From left): Susanta Hazra (corresponding author), Pritesh Keshari (first author), Rajan Yadav (co-author) and Priya Mata (co-author).

Credit: IISc

Bengaluru: New research from IISc’s Department of Inorganic and Physical Chemistry (IPC) is promising a sustainable alternative to the use of toxic organic solvents in industrial syntheses.

IPC researchers have synthesised a surfactant – through a process called micellar catalysis – from agricultural waste to help catalyse industrially relevant reactions in water, instead of organic solvents that generate substantial amounts of waste that also pose challenges in disposal. Surfactants are chemical compounds that bring down the surface tension of liquids.

Industries and chemical laboratories synthesise a wide variety of organic molecules every day. While these chemical reactions happen largely in the liquid phase, synthetic chemists are forced to use toxic organic solvents because interactions of substrates and catalysts with water can also set off side reactions and, in turn, create unwanted products.

The newly synthesised surfactant – CNSL-1000-M – is derived from cashew nut shell liquid (CNSL), a waste product generated during the roasting of cashews to separate the kernels. Pritesh Keshari, first author and PhD student at IPC, said the idea was to develop a bio-based substitute for organic solvents. IISc noted that India being the world’s second largest producer of cashew nuts made access to the raw material easier.

Surfactants are molecules with water-loving (hydrophilic) and water-repelling (hydrophobic) components. Cardanol, a hydrophobic compound in CNSL, was combined with m-PEG, a hydrophilic polymer, to create the surfactant. The surfactant molecules, when added to water, self-assemble to form spherical structures called micelles. These interactions create water-free pockets that shield substrates and catalysts that are normally sensitive to water.

This micellar catalysis mimics biological systems – many natural enzymes have a hydrophobic pocket similar to the one in micelles. The study was published in ACS Sustainable Chemistry & Engineering.

Susanta Hazra, Assistant Professor at IPC and corresponding author, said the team aimed to enable the same surfactant as a sustainable general reaction medium for all possible reactions and chemical transformations.

The surfactant was used to catalyse the formation of carbon-phosphorus bonds, an industrially important step used to make many compounds including the anticancer agent Brigatinib and organic LEDs.

“CNSL-1000-M led to 80% higher product yields in water compared to reactions carried out in organic solvents. Compared to existing surfactants, the new surfactant also gave 30% higher yields for reactions carried out in water,” IISc said.