It has been two years since naturally coloured cotton varieties in shades of brown were introduced by the University of Agricultural Sciences (UAS), Dharwad. However, the absence of dedicated research funding and restrictions on promoting these varieties have limited the cultivation of the eco-friendly plants to just 100 acres of land in Karnataka.

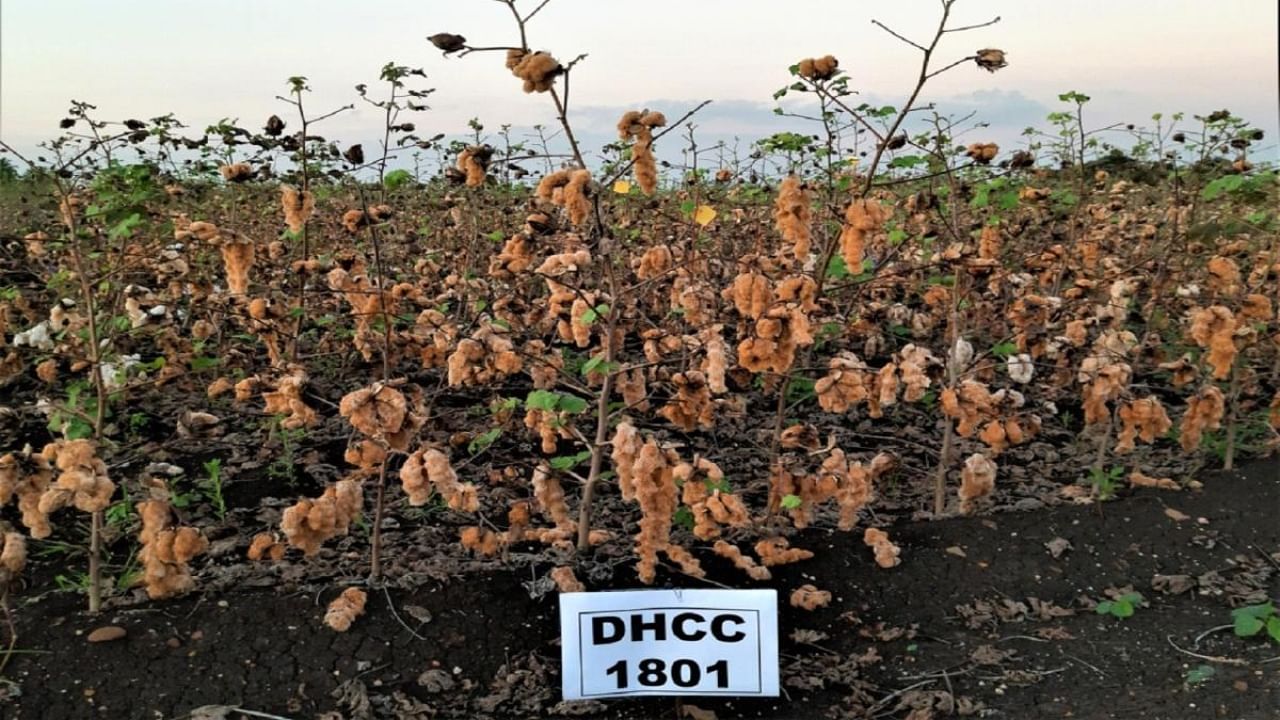

The university launched brown (dark, medium brown) and cream-coloured cotton in 2020. The brown varieties are called Dharwad Desi Coloured Cotton (DDCC-1) and Dharwad Medium Brown Cotton (DMB-225).

Naturally coloured cotton, which doesn’t require dyeing, has ecological and health advantages over common cotton varieties. But farmers cannot afford to buy the seeds as they have to pay the university a fee of Rs 3 lakh (for dark brown) and Rs 5 lakh (medium brown). So, two companies from Bengaluru have purchased the seeds from UAS, and are distributing them among the farmers, who grow it on a contract basis.

“There is immense potential for coloured cotton. Dedicated funding from the agriculture ministry and The Indian Council for Agriculture Research is required to strengthen the fibre and develop new varieties,” said Dr Rajesh Patil, a senior cotton breeder at UAS, Dharwad.

The challenges, however, haven’t hindered farmers, researchers and entrepreneurs.

Sushma Veerappa, trustee of kandu.in, one of the two companies buying the seeds, said the demand for naturally coloured cotton is growing. “The market is demanding products with lesser carbon footprint. And coloured cotton is the answer," she said.

The trust has purchased the DMB-225 variety from UAS and distributed it to six farmers, including two women in Ballari district.

The advantages

Naturally coloured cotton has several advantages over common cotton or Bt cotton in terms of returns. It also has a lower impact on the ecosystem.

Channabasappa Meti, who has been growing this cotton for the past 15 years in Uppin Betageri village since the pilot project in the 2000s, said it is remunerative. “The average yield is 10 quintal per acre. The average yield of Bt cotton is 14 to 16 quintal per acre. Each quintal of naturally coloured cotton fetches Rs 15,000 while the price of Bt cotton ranges from Rs 9,000 to Rs 11,000. Importantly, the soil’s health is protected which helps in increasing the yield,” he said.

The cultivation of Bt cotton includes excessive use of pesticides and chemical fertilisers which results in the degradation of soil health and water resources. Also, the yield of these varieties reduces year after year.

Chemicals are used even during the processing of common cotton varieties.

“As several chemicals are used in processing the fibre into cloth, the end product is not eco-friendly or skin-friendly,” said Rajesh Patil.

Naturally coloured cotton doesn’t require dyeing, which uses over 100 different hazardous chemicals such as sulphur, naphthol, nitrates, acetic acid and chromium. About 150 to 170 litres of water is used to dye one kilo of cotton. The water is generally flushed and not reused.

Clothes made from unbleached cotton are in high demand in Europe and also in countries like Japan and the US. In India, too, there has been a steady increase in affordability to purchase skin-friendly cloth made from naturally coloured fibre. These fabrics are particularly popular in children’s clothing, a study by UAS has found.

Considering its potential, UAS Dharwad has been promoting the production of this cotton. “India has the potential to become a leader in the cotton industry if dedicated funding for research and development is ensured,” Patil said.

To strengthen the concept, the university is now experimenting with green shades of cotton. Scientists are also researching ways to strengthen the fibres to make it suitable for various textile requirements.

First attempt

Although the cultivation of coloured cotton as a pilot project under the leadership of Dr B M Khadi started way back in 2000, only a limited number of farmers — less than 30 — used the seeds to cultivate brown cotton. The cotton produced in this process was woven into shirts by a nearby khadi unit. The effort, however, didn't succeed due to a lack of funding.