Inside the iron cage, you share the room with some bags of cement and a dozen innocent looking boxes. Explosives, Prashanth, the young mining engineer, with a 21-year old’s fuzz on his upper lip, explains cheerfully. For blasting at 2.45 am next morning, he adds. You stare at the silent boxes.

As the cage begins to creak in its descent, the talkative engineer explains the working of the mine. The shaft we are descending into is one of the three bore holes into the bowels of Hutti’s gold deposits.

Precise timing

The shaft leads to arious levels at which tunnels branch out, into workings. Into the holes of the sides of the tunnels that contain the gold ore, holes are bored into which the explosive charges with delayed fuses are placed with precise timings. The mine is cleared of every man jack.

And the explosives go off at the set time taking out huge chunks of ore dust and large chunks of rock with minute gold specks in them.

Four hours later, when the first shift comes at 7 in the morning, the dust is cleared and the workers separate the dust and rocks through a giant iron sieve in the ground (for lack of a better word). The debris falls through the sieve at the bottom of the mine, where it is collected by workers and dumped into a skiff to be hauled up, taken to the mill, powdered, and then through a complex process turned into a slurry containing gold which again is chemically processed and made into gold ingots.

Prashanth continues his commentary. This mine is as safe as any, anywhere in the world, he claims, with the confidence of the young.

Safety first

“We take all precautions,” he keeps repeating, a chant of the work force led by the Executive Director, D Y Venkatesh. “Safety is paramount. Profit is secondary, and even tertiary. What is profit over people’s lives? This is not China, where hundreds of mining accidents take place every year, and hundreds are not even reported,” Venkatesh says.

The cage halts. Level 2000, the inscription says on the rough rock of the tunnel. We get out. Two thousand feet. The exact depth at which 33 miners in another gold mine across the world were stuck for 70 days before being taken out on Wednesday and Thursday to the collective sigh of relief of the whole world. What is like to be entombed under a trillion tones of hard rock?

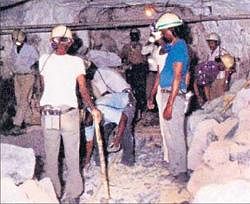

What is life at 2,000 ft. inside the maw of the earth? Inside the Mallappa shaft, unlike what imagined, it is not all dark and dank. The whole place is lit. Thanks to an engineering sleight of hand, there is fresh air blowing down from the shaft above. We head into one of the tunnels. It is just a huge long horizontal hole bored into rock. There is rock everywhere. Rocky walls, rocky ground, rocky roof.

To start a discussion on safety, I ask the young engineer a clichéd question: What did he feel when he saw the miners being taken out of Copiapo shaft?

“Happy and relieved. After all, I am a miner, and I want miners anywhere to be safe, he replies, and then gets the drift. “I have been here for two years, I have not seen a single emergency,” he says.

He points to a million steel bolts struck all over the hard roof. “When we bore into the wall and create a hollow, we keep on boring holes of the depth of 1.5 metres into the roof wherever we feel the rock is loose. We stick capsules of quick setting cement and plug in steel rods with a retaining plaque.” As safe as a baby’s crib.

After an hour and ten minutes inside the mine, we go up to the surface in the poor but sturdier cousin of Phoenix 2, the capsule used to hoist Chilean miners to the surface. No big welcoming party there for those of us coming up after 70 minutes. Well, this was not San Jose either.