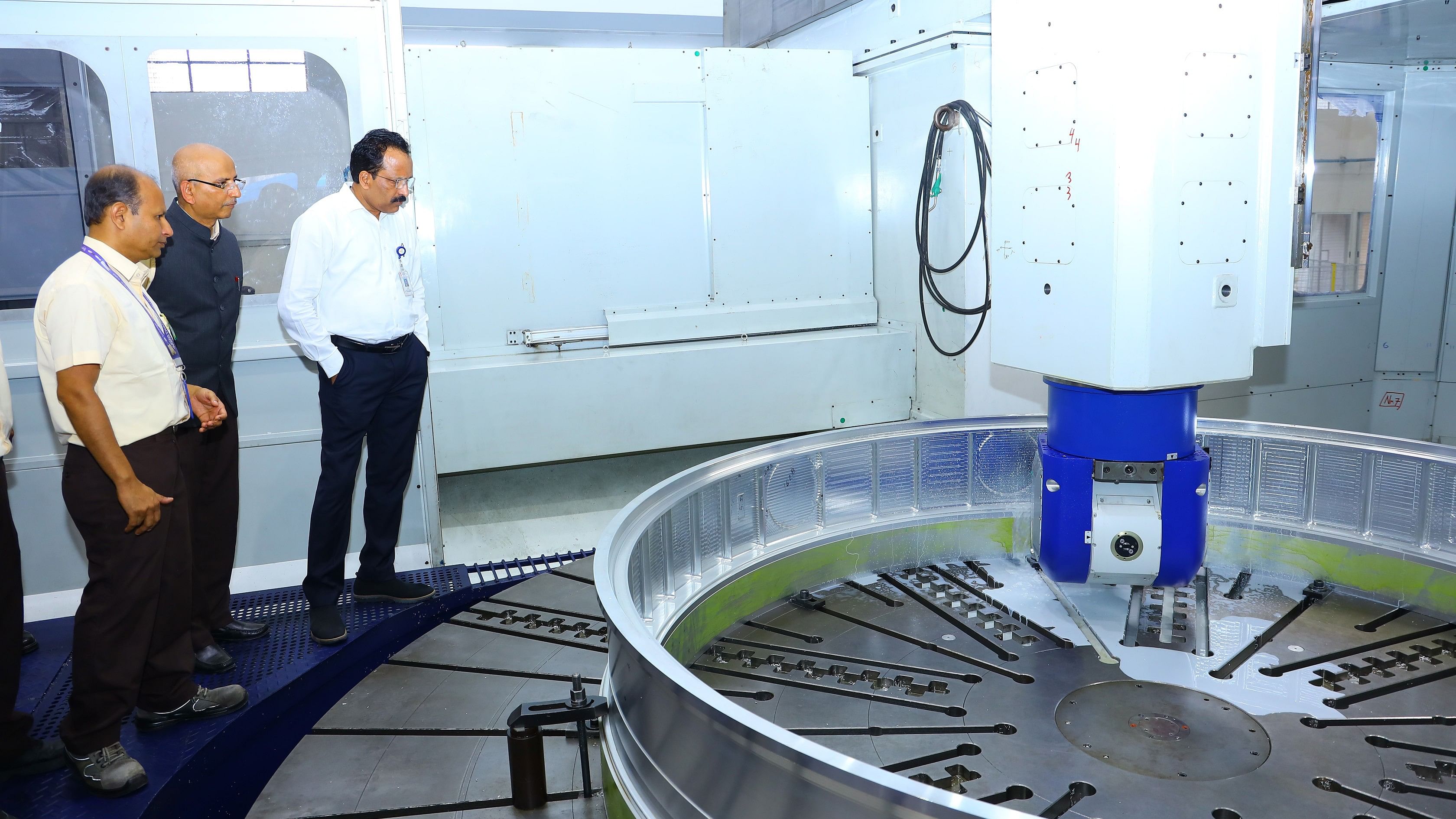

ISRO Chairman S Somanath during his visit to the new HAL facilities on Wednesday.

Credit: HAL

Bengaluru: In a capability upgrade that is expected to meet the growing production needs of ISRO, the Hindustan Aeronautics Limited (HAL) opened a manufacturing facility at its aerospace division here on Wednesday.

The new propellant tank production and CNC machining facilities will specifically cater to the production of India’s heaviest rocket, the Launch Vehicle Mark-3 (LVM3). While ISRO has an annual requirement of six LVM3 launches, the existing capacity allows for only two per year. HAL said the new facilities would address this gap and enable HAL to manufacture critical components to support the production of six LVM3s per year. ISRO Chairman S Somanath inaugurated the facilities.

The propellant tank production facility will specialise in the manufacturing of high-performance fuel and oxidiser tanks, critical components for the LVM3 4 m in diameter and up to 15 m in length. The CNC machining facility houses advanced computer numerical control machines for handling high-precision fabrication of 4.5 m-class rings and propellant tank domes of the launch vehicle.

Somanath said HAL’s enormous potential needed to be explored in the larger interest of both the organisations. The defence PSU will play a larger role in ISRO’s future missions and hence, should focus on emerging technologies, designing challenges, and take up end-to-end tasks to ease the pressure on ISRO, he said.

C B Ananthakrishnan, CMD (additional charge), HAL, said the ongoing collaboration with ISRO would accelerate human spaceflight missions and development of next-generation launch vehicles.

There are significant opportunities to work with ISRO and HAL is committed to invest further to unlock the full potential in space programmes. The day is not far off when space becomes an important vertical of HAL, he said.