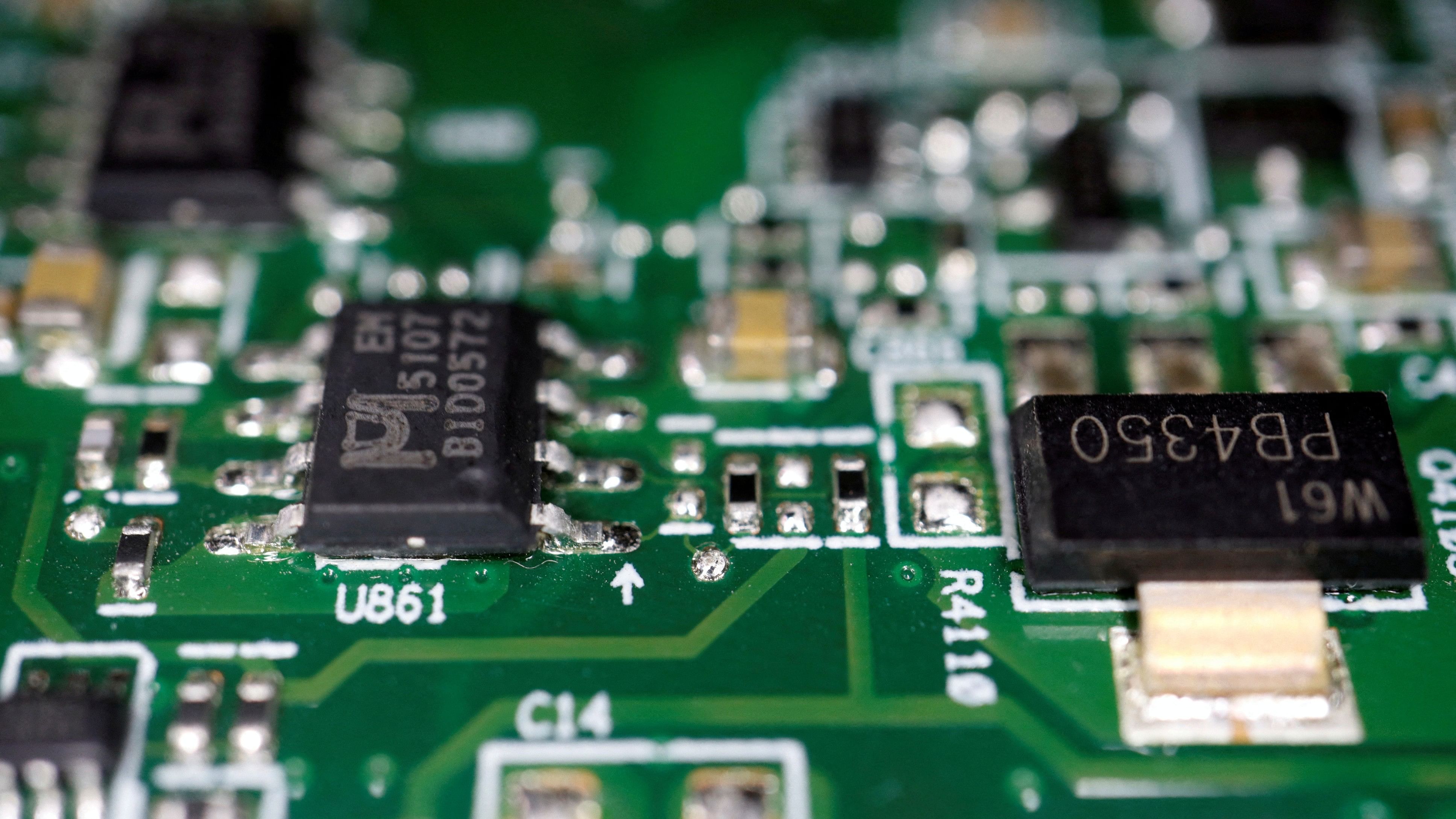

Representative image of a semiconductor chip.

Credit: Reuters Photo

India is on a path to reach a $5 trillion economy, with sustainable growth, as enunciated by IMF in its recent report. With the Micron facility being established in Gujarat and many of them likely to follow, the challenge is to energise the existing chemical industry for India’s future needs. This could also be a starting point to plug in to the global supply chains while setting up fab facilities, which is a work in progress.

Global semiconductor manufacturing primarily consists of equipment, materials, and services. This troika powers the global chip ecosystem. ‘Equipment’ comprises precision gear for manufacturing in fabrication facilities/foundries to include assembly, testing, marking, and packing (ATMPs)/outsourced semiconductor assembly and test (OSATs). ‘Materials’ comprise chemicals, minerals, and gases, all of which are critical to the manufacturing processes. ‘Services’ denote the overall value chain of logistics, packaging, and distribution.

The ‘Materials Market’, essentially utilises more than 150 varieties of chemicals and 30+ variants of gases and minerals. It is, thereby, pivotal to the entire chain of any established or aspiring semiconductor entity.

The chemical industry contributes to seven percent of India’s overall Gross Domestic Product (GDP). In terms of its size, the Indian chemical industry is statistically the sixth largest in the world, and the third largest in Asia. In terms of diversified output, it produces more than 80,000 commercial products and generates significant economic activity.

The market size of this industry in India is $178 billion, and it is expected to grow to $300 billion by 2025. Over the next five years, the industry is anticipated to grow at a compound annual growth rate (CAGR) of 8 per cent. In addition, as per the latest trends, there is a significant shift in production and consumption, leading to a higher demand statistic.

India is a leading exporter of chemicals, reaching $30 billion in FY23 — which is a significant increase from FY22. In terms of size, diversification with its key drivers of risk and return, and scale, this segment is well poised for the future.

The time is ripe for established chemical conglomerates to produce select chemicals used in semiconductor manufacturing and photolithography to include polymers, solvents, sensitisers, and additives. This will involve diversification of existing product range with an impetus on R&D, as well as improving on quality and purity to global standards.

There are three aspects which need to be highlighted. First, global chemical entities already have a presence in India, and could leverage capacities of Indian suppliers to create products for a global supply chain. Second, the Semiconductor Laboratory (SCL) at Mohali has been in operation for four decades and a considerable expertise exists in this domain. Third, select states which have a strong base in the chemical industry that could be engaged to diversify existing chemical products with related purity metrics. In addition, to make an astute business case, semiconductor manufacturing is a complex and a long process with negligible probability of switching suppliers by any manufacturing entity owing to technical issues, timelines and process considerations.

The Government of India’s programmes/policies, such as the petroleum, chemicals, and petrochemical investment regions (PCPIRs), the chemicals promotion and development scheme (CPDS) and the production linked incentive (PLI) scheme, will boost sectoral growth. Setting up of qualification laboratories, which would certify products for assessment in line with global standards, will be critical.

The chemical industry is a vital part of the semiconductor industry. It has the potential to enrich the semiconductor industry with basic chemicals, specialty chemicals, equipment, infrastructure, and even a skilled workforce. It possesses an advantage with a well-developed infrastructure of warehouses and transportation networks. India’s chemical industry needs to appreciate this opportunity to be the very fulcrum and a key enabler for the semiconductor industry.

(Anurag Awasthi is Vice President, India Electronics and Semiconductor Association (IESA))

Disclaimer: The views expressed above are the author's own. They do not necessarily reflect the views of DH